Introduction

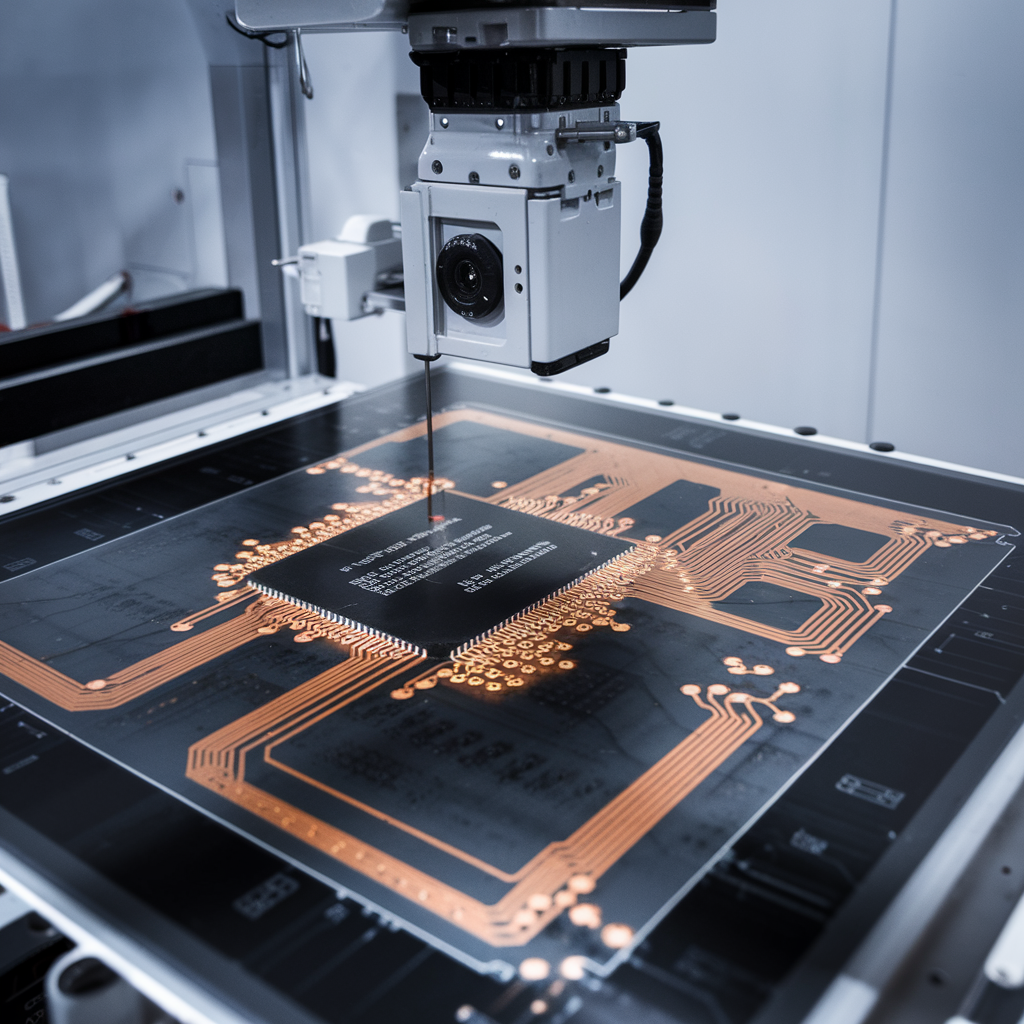

In PCB assembly, reliability is paramount. Even the smallest defect can compromise the functionality of an electronic device. X-ray inspection has emerged as one of the most effective methods for ensuring the integrity of PCB assemblies, detecting hidden defects that are invisible to the naked eye.

What is X-Ray Inspection?

X-ray inspection is a non-destructive testing method that uses high-energy X-rays to penetrate the layers of a PCB and reveal internal structures. Unlike traditional visual inspections, X-ray allows engineers to detect defects in solder joints, component placements, and internal connections, ensuring the highest level of quality control.

Common Defects Detected by X-Ray

X-ray inspection can detect a variety of common PCB assembly defects, including:

- Solder Voids: Small voids in solder joints can weaken connections and lead to failure.

- Solder Bridging: X-ray can detect unintentional connections between adjacent solder pads that can cause short circuits.

- Misalignments: Components that are slightly misaligned can be identified, preventing potential failures during operation.

Benefits of X-Ray Inspection

- Comprehensive Defect Detection: X-ray inspection can detect hidden defects that other inspection methods might miss, particularly in complex multilayer PCBs.

- Non-Destructive Testing: Unlike destructive testing methods, X-ray allows for inspection without damaging the PCB, ensuring the product can still be used if no defects are found.

- Improved Reliability: By catching defects early in the production process, X-ray inspection improves the overall reliability of electronic products.

Other Inspection Methods

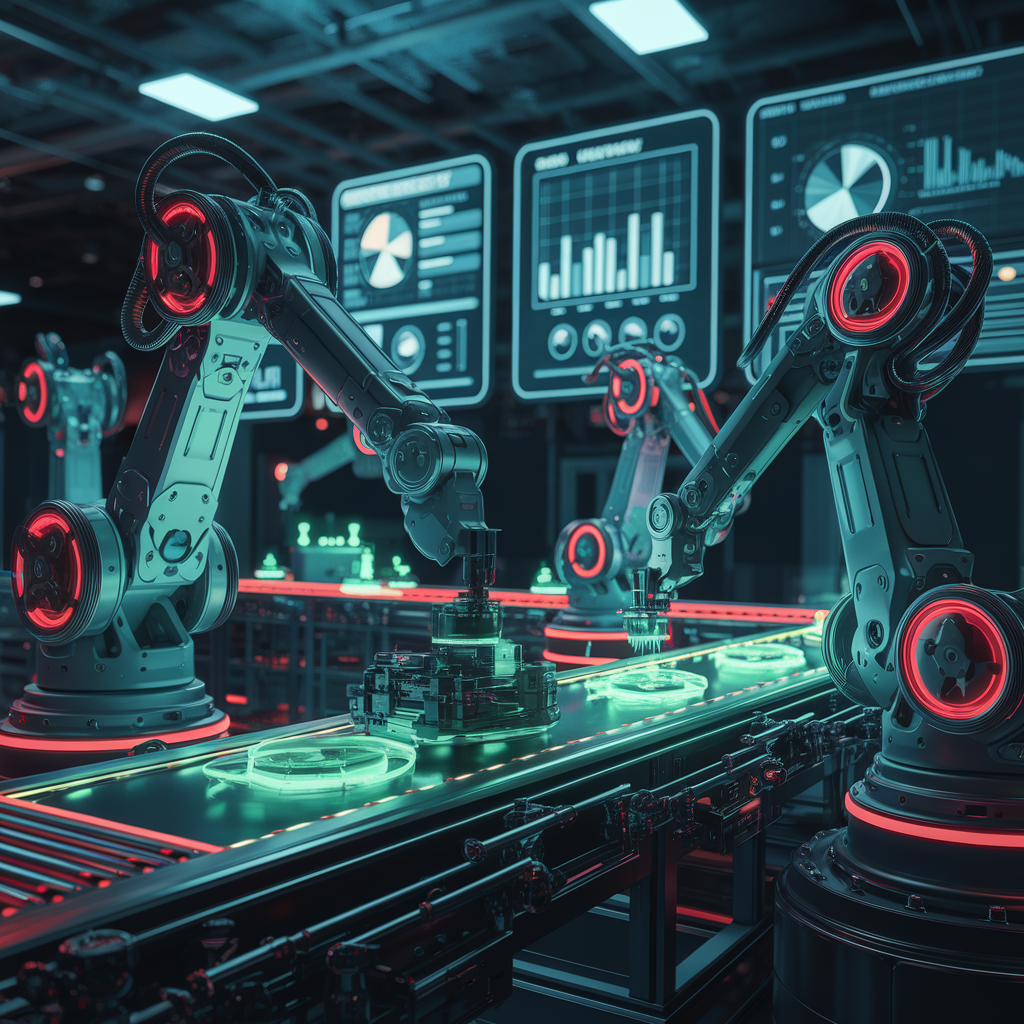

While X-ray inspection is highly effective, it is often used in conjunction with other methods such as Automated Optical Inspection (AOI) and Electrical Testing. Each method has its strengths, and combining them ensures a more thorough inspection process.

Conclusion

X-ray inspection is a vital tool in ensuring the reliability and functionality of PCBs. Its ability to detect hidden defects makes it an essential part of modern PCB assembly, particularly in high-reliability industries like aerospace, medical devices, and automotive systems.