Introduction

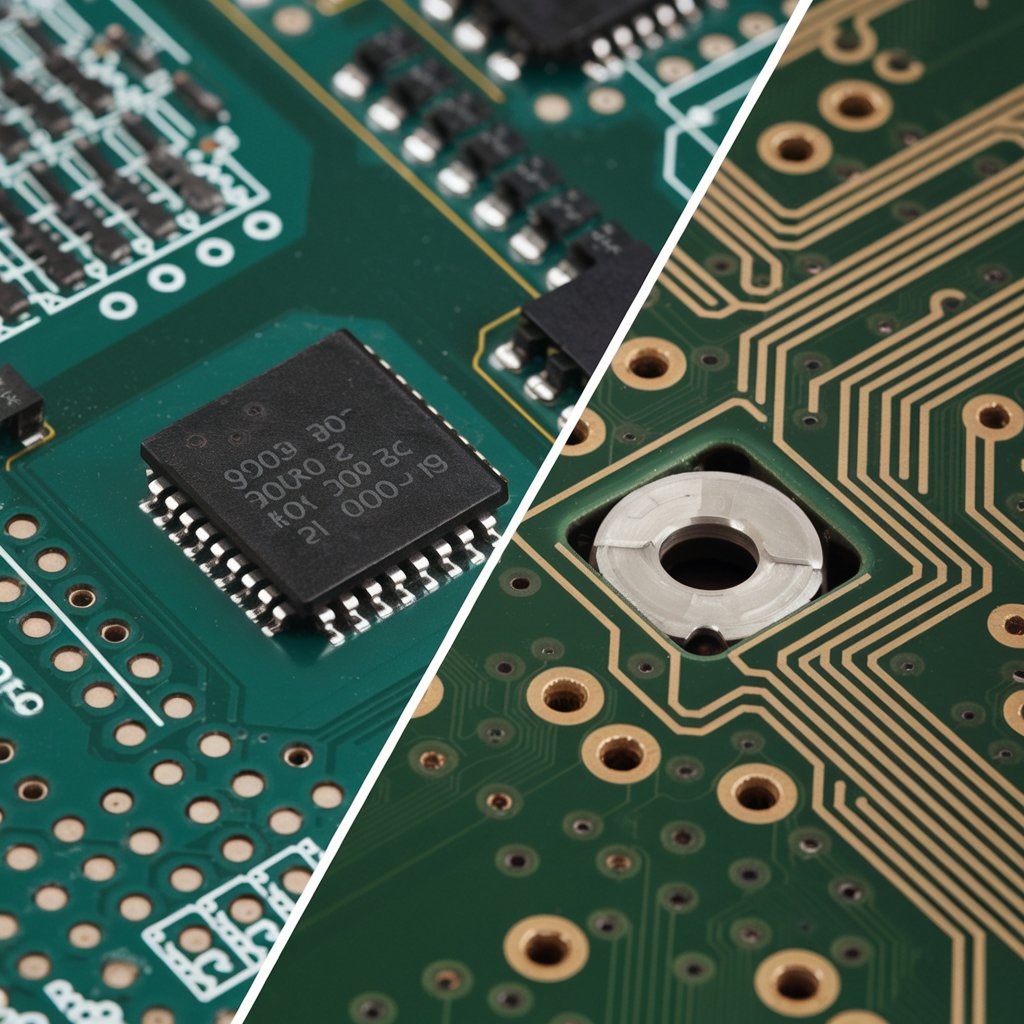

Printed circuit board (PCB) design relies on two primary assembly technologies: Surface Mount Technology (SMT) and Through-Hole Technology (THT). Each method has its advantages and is suited for different applications, making it essential to understand the differences and how they impact PCB performance and functionality.

Surface Mount Technology (SMT)

SMT is a method where electronic components are mounted directly onto the surface of a PCB. This technique eliminates the need for drilling holes in the board, allowing for more compact and lightweight designs. SMT components are typically smaller, enabling high-density PCB designs. Benefits of SMT include:

- Efficiency: SMT allows for automated assembly, reducing production time and costs.

- Compact Design: Smaller components result in more compact and lightweight devices, crucial for modern electronics like smartphones and wearables.

- Performance: Improved signal transmission due to shorter lead lengths, which minimizes parasitic effects.

Through-Hole Technology (THT)

Through-hole technology involves inserting component leads through pre-drilled holes on the PCB and soldering them on the opposite side. THT provides mechanical strength, making it ideal for applications where durability is a priority. While THT is being phased out in many consumer electronics, it remains widely used in high-stress environments such as aerospace and industrial machinery. Key advantages include:

- Durability: The mechanical strength provided by through-hole components is unmatched, making them ideal for devices subjected to physical stress.

- Thermal Performance: Through-hole components handle heat dissipation more effectively, which is beneficial for power electronics.

Comparing SMT and Through-Hole

| Criteria | Surface Mount Technology (SMT) | Through-Hole Technology (THT) |

|---|---|---|

| Component Size | Small, compact | Larger, bulkier |

| Assembly Process | Automated | Manual/automated |

| Mechanical Strength | Lower | Higher |

| Application | Consumer electronics, IoT | Industrial, aerospace, power |

| Cost | Lower | Higher |

When to Choose SMT or Through-Hole

Choosing between SMT and THT depends on the specific requirements of your project. SMT is ideal for high-density, low-cost applications like smartphones, while THT is better suited for products that require mechanical stability and high power handling.

Conclusion

Both SMT and Through-Hole technology have their place in PCB design. By understanding the strengths of each, you can make an informed decision on which assembly method is best for your project. In some cases, hybrid designs that incorporate both SMT and THT offer the best of both worlds.